|

I recently purchased a desktop CNC router from China that I have been working to both fix and upgrade. I have:

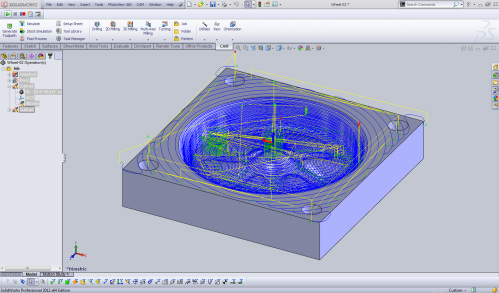

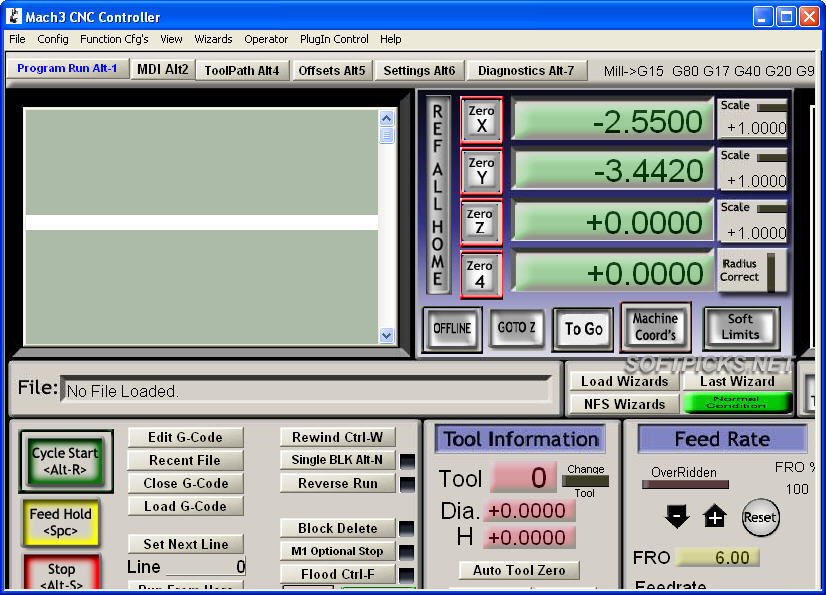

- Designed a sound damping enclosure that stores the router all electronics and tools. It also contains noise and sawdust. - Replaced the control electronics with working versions. When I received the machine only the power supply worked. - Learned how to use and debug Mach3 controller software to minimize latency and improve control. - Learned how to program parts in HSMworks to export 3 axis programs to Mach3. |

Enclosure: Blocks Sawdust and Noise

CNC routers are inherently messy machines and because I'm running it in my bedroom I wanted to keep large amounts of dust from going everywhere. To solve this problem, I designed an enclosure for machine that:

- Prevents dust from escaping - currently this is done simply by the box, but I intend to upgrade to a vacuum system that follows the router bit cleans the part as it is machined.

- Decreases the noise of the machine. I don't have a dedicated shop for this machine, so I don't want to excessively bother the people around me while running the machine. Several sheets of insulating foam absorb noise from the machine.

- Provides a location for the electronics. I replaced the control electronics, after which the electronics no longer fit within the box provided for them. This enclosure therefore mounts all of the electronics, with a dedicated fan and mounting for all of the switches.

- Stores tools in an easily accessible location.

- Provides easy access to the router for fixturing workpieces.